Cleaning and re-use options for foundry waste sand

Composting method

Aim

Organic binders are almost exclusively synthetic resins which are cured by the addition of a separate hardener or catalyst. Inorganic binders are based on sodium silicates. Combinations of foundry sand with animal manure or other organic waste sludges will be made and the different material mixtures will be carefully studied and monitored to find out the most effective way of handling and cleaning the foundry waste sand by composting method. The process will be steered in a direction that useful humus occurs with good fertilizing abilities. The end-product must meet the national regulations and limit values set in the Decree of the Ministry of Agriculture and Forestry on Fertiliser Products (24/2011): Substrate – Mixture soil (5A2).

Pictures of the construction of the composting site.

Progress of the composting tests

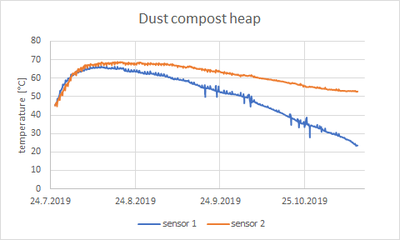

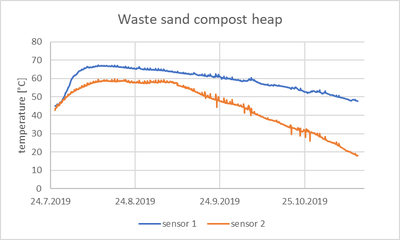

Temperatures raised rapidly to almost 70 degrees after starting the composting tests (see the temperature curves). The temperatures were well above 60 degrees in the beginning and stayed for over 2 months from July – September. According to the decree of 24/11 the temperatures should stay over 55 degrees for 14 days. The results demonstrate efficient composting process.

Temperature curves of the dust compost heap (Compost heap 1) and the waste sand compost heap (Compost heap 2).

Composting materials were analysed in the beginning and end of each test period. Wastewater samples were collected in the beginning, middle and end of each test period.

Conclusions of the composting tests

In summer 2019 the composting tests were carried out with organic binder system (phenolic) waste sand and dusts. The “pure” foundry sand type in all cases is silica sand (quartz sand).

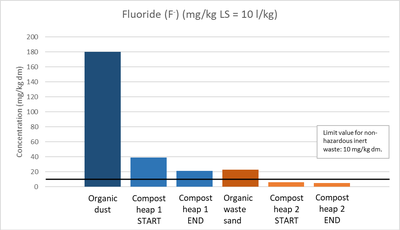

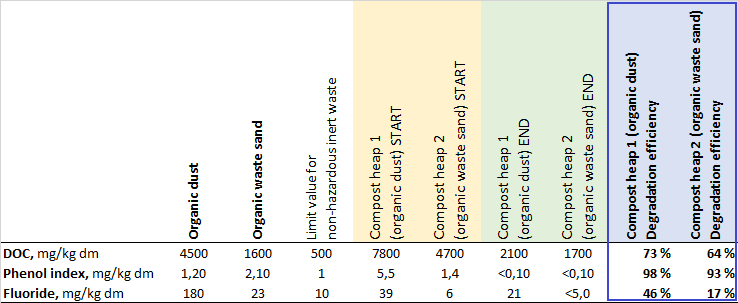

DOC concentrations of dust and waste sand samples were above the limit value of non-hazardous inert waste. Fluoride concentration was high in dust specimen and waste sand samples. The fluoride is probably coming from the fluoride containing feeders used in the molds used in all sand systems. It is expected that less foundries use the fluoride containing feeders in the future. Substitute materials are available in the market already. During the composting test fluoride concentrations were reduced below the limit values or close to it.

Fluoride concentrations of organic dust and organic waste sand and the compost heaps' start and end situations.

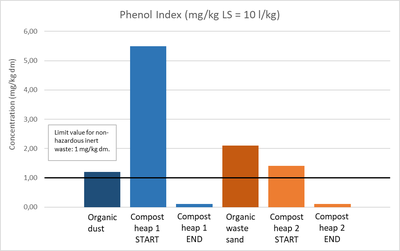

Phenol concentrations of dust and waste sand exceeded the limit value before the composting test. In addition to the sand mould system phenols can also origin from the core production when produced by cold-box system. Phenols were degraded during the composting tests, so that in the end situation the concentrations were below the limit value.

Phenol concentrations of organic dust and organic waste sand and the compost heaps' start and end situations.

Dissolved molybdene concentration in dust was above the limit value of non-hazardous inert waste, but the concentration in dust compost heap was below the limit value already in the beginning and end of the composting test.

Based on the results of the summer 2019-2020 composting tests, we can assume that the tests were successfully completed and the innovative composting end-product fulfilled the limit values set in the Decree of the Ministry of Agriculture and Forestry on Fertiliser Products 24/2011 and The EU Degree on Fertiliser Product (2019/1009) and the end-product can be re-used as substrate and for gardening and geo-construction purposes.

Degradation of the harmful substances during the composting tests demonstrate very good cleaning efficiency rates (see the table). The composting method can be considered as an effective cleaning method.

The degradation of the harmful substances during the composting tests of organic dust compost and organic waste sand compost and the cleaning efficiency rates.

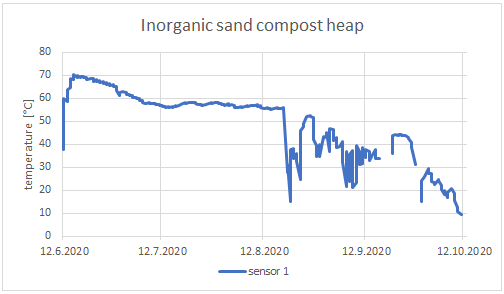

In summer 2020 composting test was carried out with inorganic binder system foundry waste sand. Based on the analyses results the inorganic binder system waste sand samples were very clean already without the composting treatment. The “waste” sand did not contain any organic or inorganic harmful compounds or metals. Based on the analyses results the inorganic binder system foundry sand could be re-used without any additional cleaning method e.g. in geo-engineering purposes as it fulfills the requirements of the Government Decree on the Recovery of Certain Wastes in Earth Construction 843/2017. It could also be mixed with other compost materials in the beginning or end of the composting process instead of virgin soil material that is needed in the compost end-product (mixture soil material).

Temperature curve of the inorganic sand compost heap (Compost heap 3).

The quality of waste waters of composting area was observed during the tests. Minor exceeding of phenol concentration (17 mg/kg) was observed in summer 2019 in the beginning of the tests and higher solid matter concentration in autumn 2020 due to the small amount of wastewaters in sampling dam when collecting the final samples.

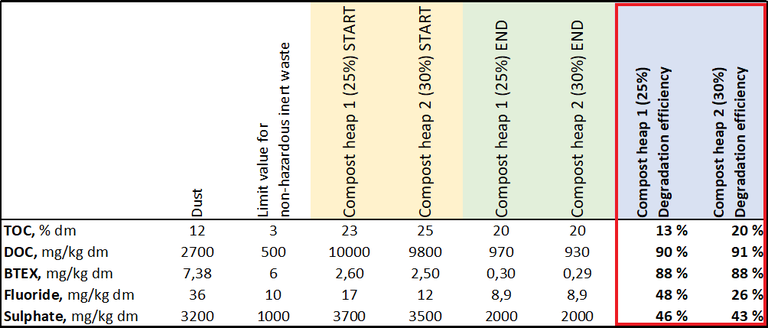

Industrial size composting tests in 2020-2021

In 2019 two smaller size test heaps of 16 and 20 tons were composted. Based on the successful tests and good results, composting tests were continued in autumn 2020-2021 with industrial scale composting heaps. Two test heaps of 91 tons and 182 tons were constructed where the foundry dust proportion was app. 25%. In these tests furan sand system foundry surplus dust with other organic materials were used.

The aim was that the harmful substances are degraded in the composting process and the compost end-product can be used for green construction and noise embankment landscaping purposes.

Aeration and heating system and pipelines were installed in the bottom of the composting heaps. Test heaps were also mixed regularly to ensure the adequate oxygen level needed for successful composting process. Waste waters from the composting field were collected into a container to avoid any leaks to environment. in total the composting process took 12 months and the post-maturing is still continued over winter time.

Results in the table below demonstrate that harmful substances were well degraded and the compost end-product met the limit values set for mixture soil material according to the MMM Fertilizers Regulation (24/11) and concerning the harmful metals and organic pollutants the limit values set in the decree of inert waste landfills (331/2013). Based on the results the mixed soil materials can be reused as landscaping and green construction material e.g. in the noise embankments.

Degradation of harmful substances of the organic binder system foundry surplus dusts in the composting tests.

Thermal reclamation

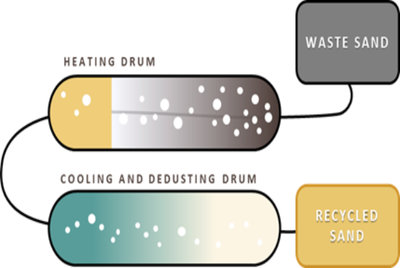

Reclamation of foundry sands is a combination of techniques used to recycle the used sand back into the moulding process. A mechanical reclaimer is often used to break down the cast moulds and bound sand back into easily flowable form. While mechanically reclaimed sand can be used partially in the moulding process, another technique is needed when maximum circulation and usage of waste sand is desired. In thermal reclamation high heat is used to combust the remains of the binding agents surrounding the sand grains.

Test process

Thermal reclamation tests were done at Finn Recycling’s existing thermal reclamation process plant in Urjala, Finland. The reclamation plant is commercially used for ester cured phenolic resin no-bake sands (APNB). The reclamation temperature i.e. the temperature of the sand leaving the thermal process was set to 650ᵒ C, which is the set temperature used with APNB sands. The process line consists of the feeder, thermal reclamation oven and a cooling screw. See figure 1. Sand quality tests conducted were the Loss on Ignition (LOI) test and the 3-point bending strength test.

Figure 1. Principle of the thermal reclamation process.

Results

Ester cured phenolic resin no-bake sand (APNB)

APNB organic sands were certain kind of reference sands in this study. Loss of ignition is clearly under the set limit value 0,3 % and 3-point bending strength test results are in good level, about 200 N/cm2.

Figure 2. Stereomicroscopy photos of unreclaimed vs. reclaimed APNB sand.

Inotec inorganic sand

LOI values after reclamation were in the level of 0,2-0,3 %. The bending strength test results show that with only thermal reclamation no significant regeneration of the used sand with Inotec takes place if the process consists only of thermal reclamation.

Peak inorganic sand

LOI values after reclamation are in the good level of 0,03 %. Lower strength levels in the start of the hardening was noticed, but after 24 h hardening time the strenght levels were in acceptable level.

Furan bonded organic sand

The reclamation results were good as expected, but the process needs a little more adjusting so that the bench and hardening times of the resulting reclaimed sands are equal to those of new sands.

Green sand

Green sand by its nature is problematic for thermal reclamation as its bonding system is based on bentonite clay. The loss on ignition of the sand was bit over 0.3% which is not perfect, but usable. Some cold-box cores were made with reclamed green sand. The green sand thermal reclamation process needs further development.

Summary

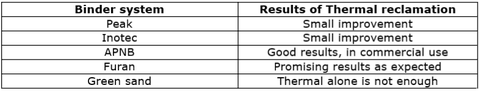

The results of thermal reclamation on the different sand systems are summarized in the table below.

Washing method

The objective of this part of the project was to demonstrate that the residual substances present in WFS could be removed sufficiently for it to have the necessary physical characteristics to be reused p.e. for cores, by washing.

At laboratory scale, we used everyday equipment and materials that could be replicated in industry. Main agents were distilled water and hydrochloric acid. Over several cycles, the WFS was washed, filtered and rewashed, progressing from distilled water to Hydrochloric acid. Towards the end the washed sand was dried in a mufla furnace.

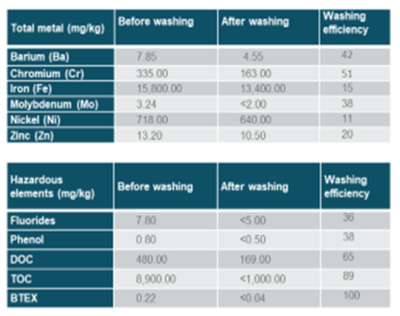

As shown in the table below, it is demonstrated that the hazardous elements from the binder were rinsed away and broken down by processes involving distilled water and hydrochloric acid.

Note: Residual sand used (30 gr to 450 gr) were from inorganic and organic sand respectively.

Mechanical, hydromechanical and ultrasonic treatment

Treatment trials carried out on inorganic sand waste have shown that hydromechanical and ultrasonic

technologies are particularly effective in obtaining an inert sand waste after treatment, or in allowing the

treated sand to be reused in foundry, geo-construction or road engineering.

Nevertheless, these hydromechanical and ultrasonic treatment processes need to be tested on an industrial

scale to verify whether these emerging technologies would be viable, compared to solutions using

conventional technologies (mechanical, thermal, thermomechanical).

Link to the CTIF summary report

Link to the CTIF report: Feasibility studies of the reuse of inorganic surplus foundry sand in core making and geo-construction